Considering obsolescence for recycling equipment

Following the most recent transfer of ownership, an expansive multi-generational waste management and recycling corporation in central California needed a business valuation for gift tax return. While a business valuation can be performed without an equipment valuation, in the case of machinery-heavy industries, the prudent option is to involve an independent equipment appraiser.

In this case, the business valuer chose to work with us primarily because of our reputation for appraising specialized machinery equipment, especially older machinery that, although still functional, has lost considerable value due to functional and economic obsolescence. The waste management company’s assets include 2 recycling lines: the “material recovery facility” (MRF) line that sorts and bales standard household recycling materials, and the “construction and demolition” (C&D) line that recycles construction materials.

The MRF (pronounced “murf”) seemed to offer an interesting equipment appraisal challenge of calculating the impact of current recycling technology – such as optical sorting – developed during that MRF’s lifetime. In addition, economic obsolescence due to local regulations that limited the MRF to 50% of its operational capacity would need to be considered, especially since the value for the valuation would be fair market value in continued use: the equipment would not be used in another location where the regulations might allow full use.

Other assets appraised included parking lot sweepers, port-a-potties, waste containers, debris bins, garbage trucks and other vehicles. Almost all these items, including the non-garbage-truck vehicles, would be valued with a straightforward sales comparison approach; valuation of the garbage trucks, however, ran into an unexpected roadblock.

Roadblock to garbage truck valuation

Sales comparison approach is usually straight forward for vehicle valuation, but while that proved true for the pick-ups, maintenance trucks, tractor trucks, flatbed trucks, and trailers (the “other vehicles”), the roadblock on this approach to garbage truck value was that appropriate sales data wasn’t available in many cases.

Garbage trucks, of course, made up most of the value in the vehicle category. Garbage trucks come in one of three main configurations: front loaders (larger commercial bins), side loaders (small residential bins), and rear loaders (green waste).

When choosing market data for the sales comparison approach, the appraiser needs to consider the value characteristics particular to the specific asset type. Value characteristics, as the term implies, are the characteristics that determine an asset’s value. Garbage truck value characteristics are loader type, meter readings, condition, and engine type relative to the CARB diesel regulations (diesel vs CNG). As a comparison, consider the 9 most commonly listed value characteristics of single-family housing: square footage, lot size, age, bedrooms, bathrooms, garage, swimming pool, fireplace, and air conditioning.

The specific value characteristics for each garbage truck were noted during the inspection, listed in the report, and considered when performing market research. The inability to find comparable market data for several of the garbage trucks, due to the lack of comparables with similar value characteristics, thwarted the sales comparison approach. Instead, because cost data is available for all garbage trucks, we turned to the Cost Approach to value garbage trucks. We were able to use the limited available market data to adequately reconcile those values to the market, providing a satisfyingly supported opinion of value.

Obsolescence of recycling lines

When valuing specialized equipment, it’s always good to talk to a knowledgeable industry expert. In this case, I had several conversations with the engineers who originally designed and built the recycling lines. Their information and insight regarding the useful life and replacement cost new of such lines provided invaluable support for the appraisal’s value conclusions. As it turned out, the interesting functional obsolescence challenge we’d anticipated in this case dissolved the more closely we looked at the equipment.

C&D line

C&D line – designed, built, and installed in 2009 – is 15 years old. Lines of this type typically need a total overhaul at 10 years old and a total overhaul is about the cost of a new line. This C&D line is overdue for a total overhaul and was thus simply valued at the minimum percent good of the cost new (installed) of the item arrived at in discussions with the engineers: the typical fully depreciated market value for items that are still “in-use” – as this line was.

MRF line

MRFs are typically considered functionally obsolete in about 10 years. This line, built and installed in 2009, was well past its normal useful life at the time of the appraisal. Like the C&D line, then, the MRF was valued at the minimum percent good of the item’s cost new (installed), provided by the engineers, in line with the typical fully deprecated market value for items that are still “in-use.”

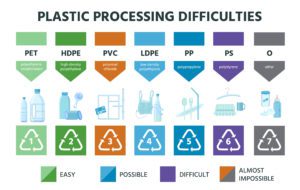

Functional obsolescence is caused by various factors: in this case, mostly the changes in the range and composition of plastic materials available for recycling – particularly the current market pressure of the industry’s difficulty in selling higher-numbered plastic types (#3-7) – and labor costs vs advanced technology, specifically the optical sorting technology mentioned previously.

Let’s take a detour here to consider the role of changing markets and technologies in the recycling industry. While this particular MRF was clearly obsolete at almost 15 years old, in a rapidly changing industry like recycling, even newer machines would be likely to have incurred functional obsolescence that would need to be considered in an appraisal for any intended use.

Optical sorting technology

A 2015 article in Plastics Technology discussed how “optical sorting equipment is making more meaningful recovery of plastics possible … [despite] the high level of customization result[ing] in a broad spectrum of plastics that need to be identified and sorted at end of life …” A 2021 article in Recycling Product News discusses the spread of optical sorters from plastics and metal applications “into fiber, glass, cartons, organics, e-scrap, and C&D recycling applications.”

In a fairly recent twist, MRFs can also be paired with artificial intelligence (AI) technology for even more flexibility and precision in materials sorting. Clearly, this is not an option that is necessary for many facilities or even desirable, and yet it underlines the rapid advancement in MRF technology that needs to be considered when appraising even equipment not at the end of its normal useful life.

Other considerations when appraising equipment include the industry market.

Recycling industry overview

Equipment valuations most appropriately include consideration of the economic situation broadly and in particular. We appraise equipment within the context of specific industries and geographic regions, such as the regional grocery store market in a buy/sell situation. In this case, we took a good look at the state of the recycling industry, including the consideration of plastics.

The Recycling Facilities industry* accepts unsorted waste and recyclable materials and sorts them into specific recyclable material categories, then processes and refines them into raw materials. Recycling facilities range from small operators that sort and package a community’s recyclable materials – such as the regional corporation that was the subject of the appraisal for a gift tax return – to large processing plants that convert collected recyclables into raw materials for resale to global markets.

In the long-term, all sizes of industry operations have grown with consumer spending and the packaging produced thereby. However, since the industry also resells recovered commodities, fluctuations in the prices of paper and plastic have caused revenue volatility in the industry. While industry revenue increase d over the five years to 20

20, it also experienced a decline of 7.3% in 2020 amid a global economic slowdown due to the COVID-19 (coronavirus) pandemic. Part of the slowdown could also be due to an unexpected hitch in plastic recycling.

Addressing the fallout from China’s plastic policy

Until January 2018, when the Chinese government banned the import of 24 grades of solid waste, including mixed paper and plastics (including #3-7 plastics), China was a net importer of a huge amount of waste from other countries, including the US. An initial response from the US recycling industry acknowledged that the industry lacked “the waste infrastructure in the U.S. to do recycling because we send mostly all of it to China and there is no secondary end market for recycled goods.”

When China’s National Sword policy ended the U.S. recyclers’ market for 65% of curbside-collected polypropylene, including nearly all bulky rigids, the Association of Plastics Recyclers (APR) focused on problem-solving, creating a marketing program to increase consistent, reliable demand for recycled plastics to ensure a robust recycling supply chain.

Another option for re-processing excess plastic may include converting it to fuel through a process called hydrocracking.

In the here and now, however, we’re determining value on recycling equipment that is already obsolete, in a well-established industry stalled by a world-wide pandemic and lack of demand for some materials.

Sorting it out

The client and business valuation expert were satisfied with solid conclusions of value for the equipment, including the 2 recycling lines, and the various containers and vehicles, including the wide assortment of garbage trucks. While we used the sales comparison where possible, and to verify the results from the cost approach, the cost approach did the heavy lifting in this assignment.

Jack Young, ASA—MTS/ARM, CPA

Equipment Appraisal & Appraisal Review

NorCal Valuation Inc.

Photo image courtesy of Gene Spesard (Flickr)

* Information in this section from IbisWorld US Industry (NAICS) Report 56292, Oct 2020